The linear heat sensing cable is a combination of a heating wire and a temperature sensor, and is widely used in electric pads. The thermal conductor detects the temperature in each zone independently, which ensures safety and efficiency. This article describes the principle of direct heating wire, usage, installation and storage precautions, specifications and test results, and the advantages and characteristics of the direct heating wire method.

Principle of direct heating wire, characteristics, use

- The principle of direct heating wire

- The heating wire is a combination of a heating wire and a temperature sensor.

- Linear thermal sensing cables are constructed from a heat-sensitive polymer that melts and triggers an alarm when a certain temperature range is exceeded.

- Independent temperature detection in each zone ensures safety and efficiency.

- Where to use the thermal wire

- It is also used in fire alarm systems.

- It checks battery heat and stops battery operation when the temperature rises to a certain level.

- It is advantageous for a variety of commercial environments such as warehouses, large barns and stables, cold storage facilities, print shops, and more.

- It has an excellent ability to detect fire and heat conditions even in small spaces.

- It is also widely used in electric pads and heating pads.

- Safety is high because it stops generating heat above a certain temperature.

- High-risk areas such as racking systems and equipment storage areas can be reinforced.

- It can effectively protect and monitor environments vulnerable to fire at construction sites.

- It is suitable for transportation facilities such as subways, airports, parking lots, escalators, and rail systems.

- Ideal for unique and vulnerable spaces such as museums, sports arenas, historical monuments, barns or stables.

- Precautions for installing and storing the heating wire

- When installing the heating wire, external shocks and sudden bending should be avoided.

- When storing, it is recommended to avoid direct sunlight and store in a dry place.

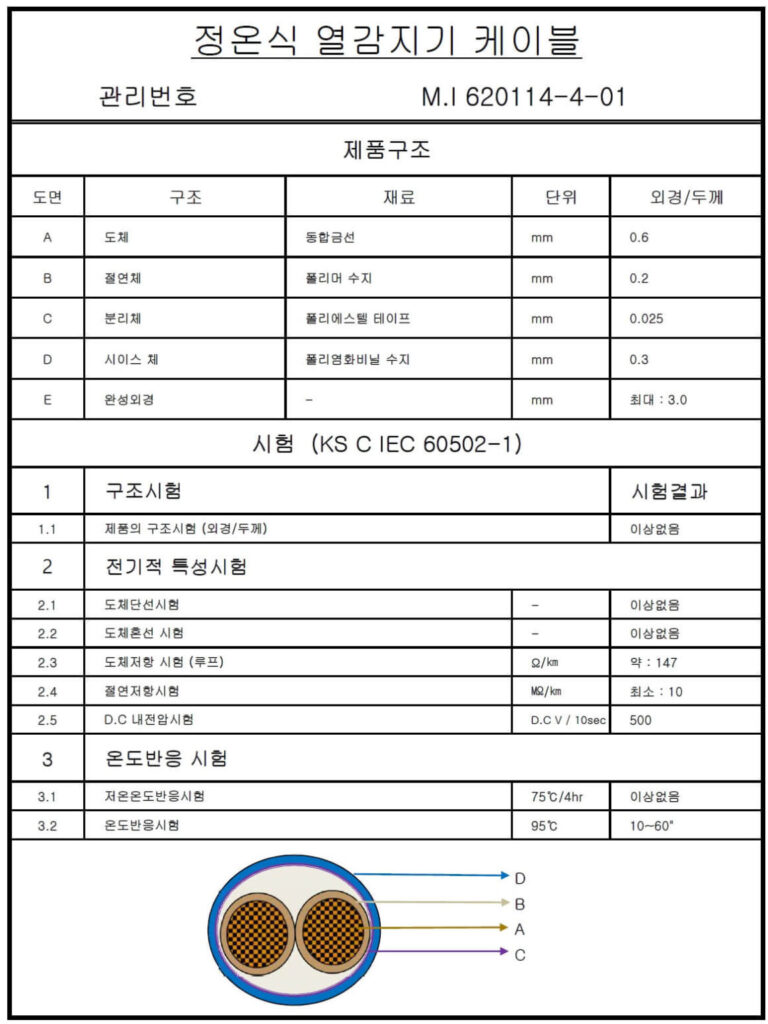

- Specifications and test results of direct heating wire

- It is necessary to understand the specifications and test results of the direct heating wire, and to know information such as temperature sensing method and wire capacity.

- Nylon thermistors have resistance that changes with temperature and melts above a certain temperature.

- Advantages and characteristics of direct heating wire method

- The thermal wire can sense the temperature in the entire section, and there is no need to separately install the temperature sensor and bimetal.

- The heating wire is effective in detecting the temperature generated from the heating wire and activating the safety device due to the combination of the heating wire and the sensing wire.

- Precautions when manufacturing a heating wire

- If the direct heating wire is designed to melt at 90 degrees and short, it must be made to melt at exactly 90 degrees. That’s the skill. Korea NTC Co., Ltd. has such technology.

linear heat sensing cable specifications

This is a sample data value for production and use of constant temperature type heat detector cable manufactured by Korea NTC Co., Ltd.