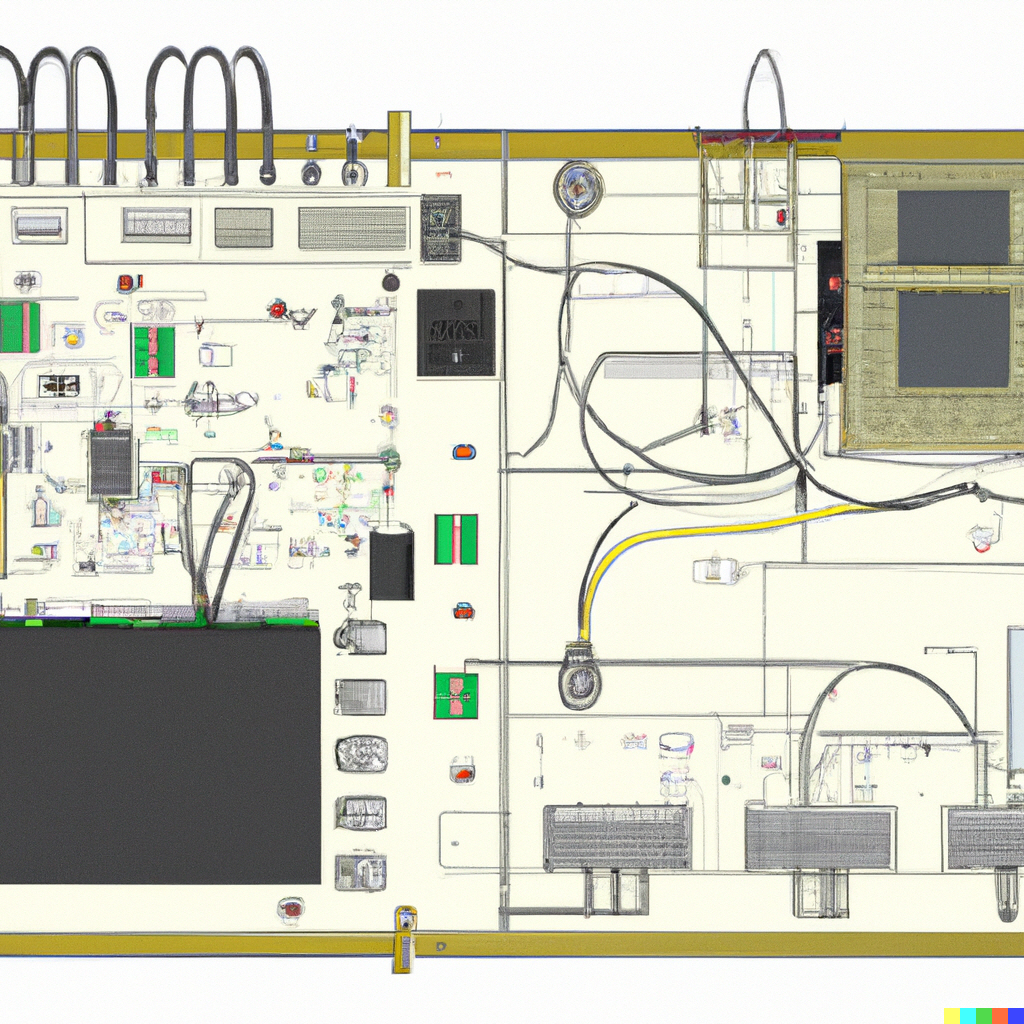

We, Korea NTC Co., Ltd., are commissioned by dozens of semiconductor equipment companies to develop and manufacture wires for equipment and supply them. With know-how accumulated over many years, it is possible to develop, mass-produce, and deliver products according to the requirements of semiconductor equipment companies. Introducing the wires we manufacture.

List of Semiconductor Equipment Available for Korea NTC Cable

Korea NTC Co., Ltd. has been commissioned to develop and manufacture wires for the following semiconductor equipment.

- Photolithography Equipment : The transfer process is one of the most critical steps in the semiconductor manufacturing process. Transfer equipment serves to print circuit patterns on semiconductor wafers using light. Commonly used equipment includes steppers and scanners.

- Etching Equipment : The etching process is used to remove unwanted parts from a wafer. This machine creates a pattern by leaving only the parts you want and removing the rest.

- Deposition Equipment : This equipment is used to deposit various materials onto wafers. Deposition processes include physical vapor deposition (PVD) and chemical vapor deposition (CVD).

- Ion Implantation Equipment : This equipment implants ions into the wafer to change the characteristics of the semiconductor.

- Annealing Equipment : This equipment is used to heat the wafer to a high temperature to change the arrangement of atoms and improve the properties of the material.

- Inspection/Measurement Equipment : This equipment is used to control and inspect the quality of the semiconductor manufacturing process.

Types of wires entering semiconductor equipment

- Power cable : It is used to supply the power required for the operation of the facility. Electric wire is generally used for high-power equipment, and its thickness and material depend on the amount of power.

- Data Cable : Used to transmit data for control and monitoring of equipment. These generally transmit low-power signals, and types include Ethernet cables, USB cables, and serial cables.

- Coaxial Cable : Used to transmit high-frequency signals. It is used in equipment that transmits radio frequency (RF) signals, such as ion implantation equipment or deposition equipment.

- Sensor cable : Used to transmit signals from sensors used to monitor the condition of equipment. These cables usually transmit low-power signals.

- High-Temperature/High-Voltage Cables : Some equipment, particularly thermal equipment, may require cables that operate in high-temperature or high-voltage environments. These cables are made of special insulation and materials.

Matters to be considered when requesting semiconductor equipment wire production

- Determining equipment needs : Each type of semiconductor equipment has unique requirements. The operating environment of the equipment (temperature, humidity, pressure, etc.), the type and power of the signals, and the size and placement of the equipment must be considered. These requirements are necessary to determine the material, structure, size, etc. of the wire.

- Performance of wires : The performance of wires directly affects the quality of signal transmission and the reliability of equipment. Performance metrics such as power dissipation, signal distortion, and noise resistance should be checked.

- Durability and longevity : Since the wire is used continuously throughout the life of the equipment, it needs sufficient durability and longevity. Resistance to high temperatures, high pressures, chemicals, vibrations, etc. must be verified.

- Safety : Since wires often carry high power or high-frequency signals, safety is an important requirement. It is necessary to check the ability to protect equipment and users from overvoltage, overcurrent, electrical fire, electric shock, etc.

- Reliability of the manufacturing company : The technical capability, quality control, service, reliability, etc. of the manufacturing company should be evaluated. A manufacturing company’s credibility can be verified through previous successful projects or referenced customers.

- Pricing and Delivery Time : The price and delivery time of the wire will affect the cost and schedule of the project. While comparing prices and delivery times, be aware that a lower price may not always be a good choice.

- After-sales support : Since problems may arise even after equipment installation, you should check the manufacturer’s after-sales support service. In particular, you should check the warranty period, warranty conditions, repair services, and technical support.

Each cable has a different material and structure depending on its purpose, signal type, signal power, environmental conditions, etc., and performance and durability vary accordingly. Since the selection of cables has a significant impact on the stability and reliability of the facility, the selection of appropriate cables is very important in the semiconductor manufacturing process.

Korea NTC Co., Ltd. has accumulated a lot of know-how through cooperation with various companies for a long time. If you contact our company, we will respond right away and start production.